A comprehensive guide to finding the best industrial absorbents and spill

containment solutions to keep your facility clean and safe.

Understanding Industrial Absorbents: What You Need to Know

In the realm of industrial safety and environmental protection, few tools are as essential as sorbents, most often referred to as industrial absorbents. Absorbent materials stand as the first line of defense against spills and leaks in virtually every industry. In this extensive guide, we will delve deeper into the world of industrial absorbents, exploring their history, the diverse types available, including natural options such as coir, and the benefits of reusable absorbent materials.

A Brief History

The concept of using absorbent materials to manage spills and soak up liquid traces back centuries to early civilizations, then with the advent of the Industrial Revolution came the development of more specialized absorbents. The 20th century witnessed significant advancements in absorbent technology, which led to the creation of synthetic absorbents. Regulatory mandates further propelled the development of absorbents tailored to specific types of spills, such as oil-only and chemical absorbents. Today, industrial absorbents continue to evolve, incorporating sustainable materials and advanced manufacturing techniques to meet the growing demands of modern industries while minimizing environmental impact.

Types of Absorbents Available

The purpose of industrial absorbents is to contain and cleanup liquids such as oils, chemicals, water, and other fluids. There are 5 primary categories of industrial absorbent solutions, each designed to fulfill a particular set of needs.

- Universal Absorbents - Multipurpose universal absorbents are versatile and capable of absorbing a wide range of liquids, including grease, water, coolants, and solvents.

Pros:

- Versatility in absorbing various liquids.

- Quick absorption rates.

- Available in different forms for diverse applications.

Cons:

- May not be as effective for highly viscous liquids.

- Some types may not be suitable for aggressive chemicals.

- Oil-Only Absorbents - Designed specifically to absorb hydrocarbons such as oil and petroleum-based fluids, oil-only absorbents need to be both oleophilic (oil-attracting) and hydrophobic (water-repellent), making them ideal for oil spill cleanup on land and water or wet environments.

Pros:

- Excellent for oil spill containment and cleanup.

- Floats on water, facilitating marine spill response.

- Minimal water absorption, maximizing oil absorption capacity.

Cons:

- Limited versatility compared to universal absorbents.

- Not suitable for spills involving water-based liquids.

- Chemical Absorbents - Chemical and HazMat absorbents are specially formulated to handle hazardous or aggressive chemicals. They are engineered to neutralize and absorb acids, bases, corrosive liquids, and toxic substances safely.

- Designed to handle hazardous chemical spills safely.

- Neutralizing capabilities reduce the risk of chemical reactions.

- Suitable for laboratory and industrial environments dealing with corrosive substances.

Cons:

- Higher cost compared to universal or oil-only absorbents.

- Limited effectiveness for non-chemical spills.

- Granular Absorbents - Granular absorbents consist of small particles or granules made from materials like clay, silica, or diatomaceous earth. Clay-based absorbents, also called “kitty litter,” are among the most widely used across every industry.

Pros:

- High absorbency rates due to increased surface area.

- Ideal for outdoor spills or uneven surfaces.

- Relatively low cost.

Cons:

- Dust creates potential inhalation hazards and health issues.

- Typically requires more product compared to other absorbents.

- May need additional cleanup after use due to residue.

- Spill Kits - Spill kits are comprehensive packages containing a variety of absorbent materials, PPE (Personal Protective Equipment), and cleanup accessories tailored for specific spill types or industries.

Pros:

- Convenient and readily deployable for spill response.

- Contains all necessary materials for quick cleanup.

- Helps maintain compliance with safety regulations.

- Compact size makes it ideal for commercial trucks or other vehicles, and for quick, self-contained spill response at schools, arenas, hotels, and more.

Cons:

- Higher initial investment compared to individual absorbent products.

- Requires regular inspection and replenishment of components.

Industrial Absorbent Solutions

Absorbent Pads and Mats - Absorbent pads and absorbent surface mats are flat, flexible materials often used for cleaning up spills on floors, especially oil, chemical, or water spills. They are particularly effective for small to medium spills or as a preventative measure where leaks may occur.

Absorbent Socks or Booms - Absorbent socks are flexible, tube-like materials filled with absorbent materials. They are primarily used to contain spills and prevent them from spreading by forming a barrier around the spill.

Absorbent Pillows - Absorbent pillows are larger and more absorbent than pads, designed for containing bigger spills. Their absorbency rates vary but are generally higher than pads due to large size and volume.

Tips for Selecting the Right Absorbent

The right absorbent product can make a significant difference in maintaining workplace safety, environmental compliance, and operational efficiency. There are 7 key characteristics to consider when choosing Industrial Absorbents:

- Type of Fluid Absorbed

- Speed of Absorption

- Absorbency Capacity

- Ease of Application

- Health Risks

- Environmental Impact

- Cost Efficiency

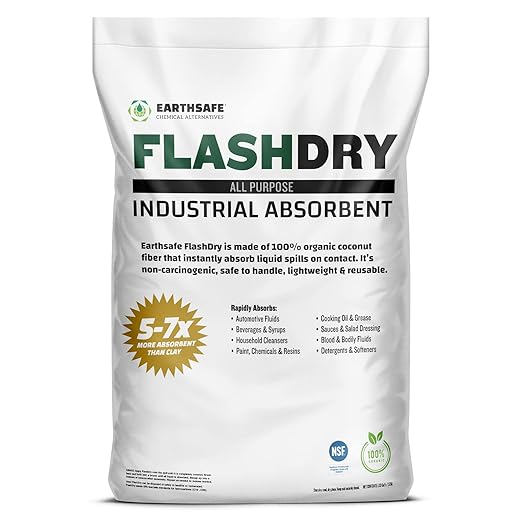

Natural Absorbents: The Case for Coir

In recent years, there has been a growing interest in natural absorbents due to their eco-friendly nature. Absorbents made from natural materials range from sand and peat moss to sawdust and cellulose fibers. However, most natural materials are not readily renewable or may necessitate extensive processing. One natural resource gaining traction is coir, derived from the fibrous husk of coconuts. Coir exhibits excellent absorbent properties, making it suitable for a wide range of spill containment needs across many industries.

Features and Benefits of Coir Absorbent

- High absorbency: Coir fibers boast impressive absorbent capabilities, efficiently soaking up liquids and containing spills.

- Safe, Non-toxic: Coir is 100% organic, Silica-dust free.

- Biodegradable: Unlike many other absorbents, Coir is biodegradable and safe for landfill disposal, minimizing environmental impact and promoting sustainability.

- Renewable sourcing: Coir is sourced from coconut husks, a byproduct of coconut production, making it a renewable and readily available resource.

- Versatility: Coir can be used to absorb various liquids, both hazardous & non-hazardous, including oils, chemicals, and water, making it a versatile option for spill cleanup.

- Reusable: Coir absorbent can be reused, thereby extending the lifespan of the absorbent, minimizing waste, and reducing costs.

- Lightweight and Easy-to-Use: Coir requires less material yet is multi-times more absorbent than Clay.

- Remove Residues: Coir requires no secondary cleanup, saving significant cleanup time.

- Cost-effective: Natural Coir is less expensive than synthetics

Industries That Rely on Industrial Absorbents

Industrial absorbents are a critical component in managing spills and leaks across a wide array of fields. When fluids are involved, spills are inevitable, posing environmental risks and safety hazards. Industrial absorbents play a pivotal role in containing, absorbing, and safely cleaning up of spills. 10 of the most common vertical applications include:

-

Manufacturing Facilities

Manufacturing plants often deal with oil, coolant, or chemical spills from machinery and equipment. Industrial absorbents are used to contain and clean up these spills, preventing workplace accidents and environmental contamination.

-

Laboratories

Laboratories handle a wide range of hazardous chemicals and substances. Chemical absorbents play a crucial role in safely managing spills and leaks, minimizing exposure risks to laboratory personnel and the environment.

-

Transportation and Logistics

Transportation industries, including shipping, trucking, and railroads, face the risk of oil and fuel spills during transportation. Oil-only absorbents are essential for containing and mitigating these spills to prevent environmental damage.

-

Food Processing

Food processing facilities must adhere to strict hygiene and safety standards. Universal absorbents are used to clean up spills of oils, liquids, and food substances, ensuring a clean and safe working environment.

-

Construction Sites

Construction sites often encounter spills of fuels, lubricants, and hydraulic fluids from machinery and vehicles. Granular absorbents are commonly used to absorb and contain these spills, minimizing environmental impact and safety hazards.

-

Energy, Oil and Gas

Oil and gas companies utilize oil-only absorbents extensively to manage spills and leaks during drilling, refining, and transportation operations.

-

Chemical Manufacturing

Chemical manufacturers rely on chemical absorbents to handle spills of hazardous substances safely and comply with strict regulatory requirements.

-

Automotive

Automotive industries use absorbents to manage spills of oils, lubricants, and fluids during vehicle maintenance and repair activities.

-

Healthcare

Hospitals and healthcare facilities utilize absorbents to manage spills of blood, bodily fluids, and chemicals, ensuring a hygienic and safe environment for patients and staff.

-

Aerospace

Aerospace companies employ absorbents to manage spills of fuels, hydraulic fluids, and lubricants during aircraft maintenance and manufacturing processes.

Navigating the World of Industrial Absorbents

In conclusion, industrial absorbents stand as indispensable tools for managing spills and leaks in diverse industrial settings. From their historical roots to modern advancements encompassing natural and reusable options, the landscape of absorbent materials continues to evolve, driven by the dual imperatives of safety and sustainability. By understanding the different types of absorbents available, their features and benefits, and their applications across various industries, organizations can make informed decisions to protect their personnel, assets, and the environment, ensuring a cleaner, safer, and more sustainable future.